Industrial Water Supply Treatment

Industrial Wastewater Treatment

Reclaimed Water Reuse and Zero Emission

Municipal Sewage Treatment

In designing integrated membrane systems, industrial evaporator supplier Geeking Tech fully embodies the concept of engineering equipment integration. It efficiently integrates a complete MBR membrane module with other process technologies into skid-mounted equipment or a container, and adds physical, chemical, and membrane treatment process equipment according to the water inlet quality condition. We can provide integrated supply, membrane module design, low-cost operation and maintenance, and efficient and stable operation for different application scenarios, water quality, and quantity.

Our innovative integrated membrane systems reduce footprint while achieving higher recovery rates. Discover how integrated membrane systems can optimize your plant’s performance while meeting environmental regulations. Upgrade your filtration process with cutting-edge integrated membrane systems designed for efficiency, durability, and cost savings. In designing and selecting models, the following factors should be considered comprehensively:

Processing capacity

Processing effect requirements

Membrane materials and types

Membrane component form

Operating conditions

Pre-processing and post-processing technologies

Cleaning and maintenance

Economy and sustainability

Regulations and standards

Energy conservation and environmental protection: reducing energy consumption and wastewater and exhaust emissions

Investment economization; low maintenance costs, high cost-effectiveness, and low transportation costs

System integration: complete equipment, fully functional system, short installation time

Equipment miniaturization: compact equipment, small footprint, convenient operation and maintenance, and easy mobility

Intelligent operation: automatic operation, easy operation, remote fault alarm

High quality water production: high interception rate of bacteria and viruses, guaranteed water quality

System modularity: great flexibility and strong scalability

Compact equipment: saving transportation costs and shortening installation hours

Simplified operation: convenient assembly, simple maintenance and management

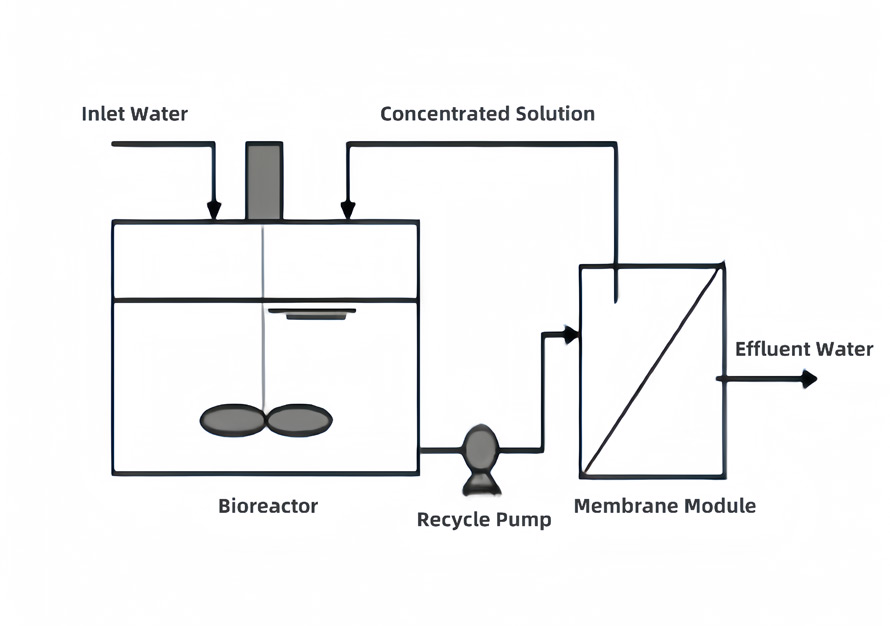

The main working principle of integrated membrane equipment is combining membrane wastewater treatment technology with traditional biological treatment processes to improve efficiency of wastewater treatment and water yielding quality. The core working principles can be summarized into three aspects: pre-treatment, membrane separation, and post-treatment.

Pre-treatment system: It mainly removes suspended matters, organic matters and other impurities from raw water through physical or chemical methods to reduce pollution burden on the subsequent membrane treatment system.

Membrane separation unit: Membrane technology is adopted to deeply purify water. During the membrane separation process, water passes through the membrane under pressure, and the membrane can effectively intercept pollutants such as viruses, bacteria, suspended matters, and macromolecular organic matter, thereby achieving water purification and separation.

Post-treatment system: It mainly involves further treatment of the water after membrane treatment to meet specific water use standards or improve water quality.

Industrial Water Supply Treatment

Industrial Wastewater Treatment

Reclaimed Water Reuse and Zero Emission

Municipal Sewage Treatment

Deep Treatment of Drinking Water

Distributed Sewage Treatment

Membrane Seawater Desalination

Desalination of Brackish Water

Special Separation

Emergency Rescue

Landfill Leachate Treatment

Oil Containing Wastewater Treatment